If moisture presents in either the substrate or the transfer paper it can have an adverse effect on the sublimation process.

1.Common problems include color shifting (where colors lose accuracy)

2. Bleeding of the image

3. Uneven transfer of solid filled areas of a design.

If humidity too high, will influence the sublimation paper dry speed very low, the worse is caused paper touching your print head.Most of customers crazy for this problem.

Therefore, indoor humidity control is very important.

What humidity in print should we pay attention to?

How do we do that?Avoid printing because humidity affects the printing effect.

1.The moisture that comes with your clothes.

The first step in minimizing the effects of humidity is to always store your transfer paper in a dry place. If dealing with poly-performance apparel you can pre-press the shirt for about five seconds if you suspect there may be moisture in the fabric. For other substrates, you can “warm” them on the heat press without closing it.

2. Indoor humidity

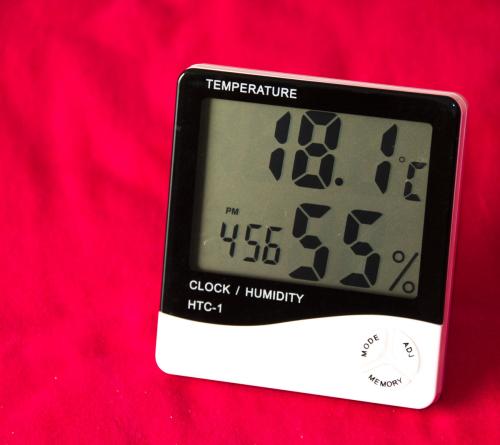

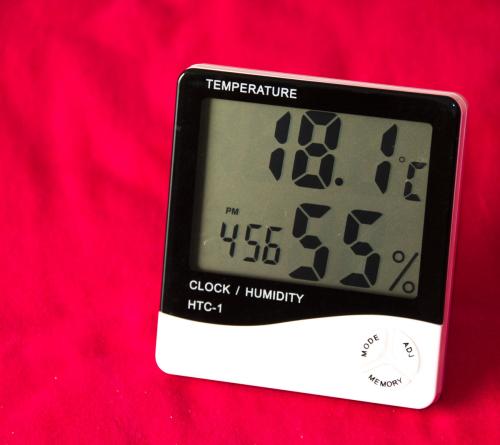

We should control the indoor humidity 50-60%,Sublimation printing use around 50-60% humidity, it can keep paper smooth printing, and have sublimation paper and sublimation ink dry quick.If your indoor humidity is too high, Open your air condition, and if you have budget, you can make the printing room at the stable humidity and stable temperature.

3.Paper is stored in the remaining part after use.

Usually you will put the used paper rolls down and put them on the side.Paper material itself has adsorption force, it will be around the indoor moisture absorption, cause paper moisture, printing effect, therefore, we will be surplus paper roll should be sealed packing in cartons, such secondary out when using, the effect of the paper will not change.

However, an environment that is too dry isn't any good either as it can cause print head nozzle loss issues. For best results, check the recommended ranges of humidity for your equipment, then purchase a hygrometer to measure your environment. If adjustments are needed, you can purchase either a humidifier or de-humidifer.

Contact Us

Subtextile Co. Ltd.

Add: East Street No.7-2 ,Waisha Village, Baguazhou, Qixia District, Nanjing City, JiangSu Province, China

P.C:213000

Export office:

699-18 ,Xuanwu Blvd.,Nanjing City,Jiangsu,China

P.C:213000

Tel:+86 25 85416407 (GLOBAL)

Fax:+86 25 85416407 (GLOBAL)

Cell:+86 17798509619

E-mail:[email protected]

Make a complaints

Mobile:+86 17798509619(English,Chinese)

+86 17798509612 (English,Chinese)

Email: [email protected]

Keep yourself posted by following us on social media:

Choose sublimation paper? Focus on quality over price

Choose sublimation paper? Focus on quality over price

7 Factors To Consider Before Choosing A Digital Textile Printer

7 Factors To Consider Before Choosing A Digital Textile Printer

2024 Apparel Decoration Industry Trends

2024 Apparel Decoration Industry Trends

What are the features of digital textile printing equipment

What are the features of digital textile printing equipment